I've always wanted a metal Power Sword for my MOTUC He-Man, and not just a chromed plastic one. So I decided to make a custom sword. After the series of photos of King Grayskull forging the sword below you'll find a description of the process I went through to make the sword. The King Grayskull photo shoot was inspired by the cover of a recent issue of the He-Man & the Masters of the Universe comic by DC Comics.

So I have access to a small furnace (melting pot) and other accessories to cast small items out of a lead free pewter. Of course to cast something I need a mold. So I needed an original to make the mold from. I decided to use a spare Prince Adam sword from the Classics line. You can't beat the Four Horsemen's sculpt. So I set up a form of melamine coated boards to contain the plaster. The fours sides are clamped together and caulked to a bottom board. The form was filled with a thin layer of clay and the sword was pressed in half way. (Picture below is without clay)

I mixed up a small batch of plaster and poured it into the mold. Then I had to allow it to harden and dry.

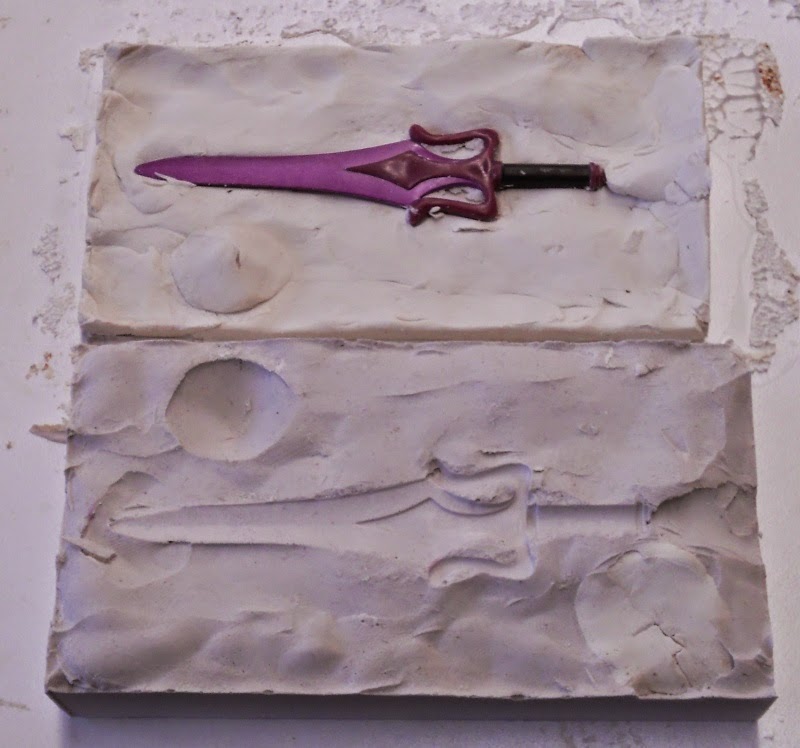

Here you can see the plastic sword in half the mold. This mold is the reverse of the clay that was in the bottom of the form. The large crater and funnel at the end of the handle were created by large lumps of clay. The crater is there to establish a registration point between the two halves of the mold. The funnel is there for pouring metal into the mold.

The first half of the mold and the sword were flipped over and placed back inside the form. A small lump of clay was placed in the funnel to keep that shape from being filled in. The original half of the mold and the sword were coated with a little Vaseline to make it easy to separate the two halves. Then a new layer of plaster was poured on top to create the second half.

Above is a photo of the two halves of the mold. The high heat of the molten metal cause rapid degradation of the mold. I knew I'd only be able to produce a limited number of swords. After the mold was given plenty of time to dry I began casting swords. In the beginning the swords came out fairly clean with only a little flashing that needed to be cleaned up. Over time, as the mold wore out, the castings got worse and worse. I did get one sword with really interesting flashing that looked like lightning traveling down the blade. I painted the flashing a metallic blue to give the sword and energy effect. After that sword, the mold would no longer hold metal. It just ran out of the bottom. So the last thing I did was pour metal into just half the mold. This sword had a rounded overflow that was painted yellow and orange as my "being forged" sword. I carefullly cleaned up the best two castings of the standard sword and painted up the two forged swords I made. I sent a set to a fellow He-Man fan and of course I kept the one of a kind energized Power Sword.

I want one!!!!!!!

ReplyDeleteThat's a great sword. Nicely done. Have you done other castings?

ReplyDeleteI made a few Han Solo in carbonite figures using the silicone ice cube tray. I wouldn't use it for food anymore. Some of the metal seems to have gotten fused to the mold. I made a mold and cast some Destro head from GI Joe. I never cleaned any of them up and tried putting them on a figure (probably top heavy). I also created a sterling silver Cobra Commander head using an investment casting process in college. I've also cast a few machine parts in a foundry before.

Delete